GE Aeroderivative Gas Turbines Brochure Page 17

- Page / 31

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

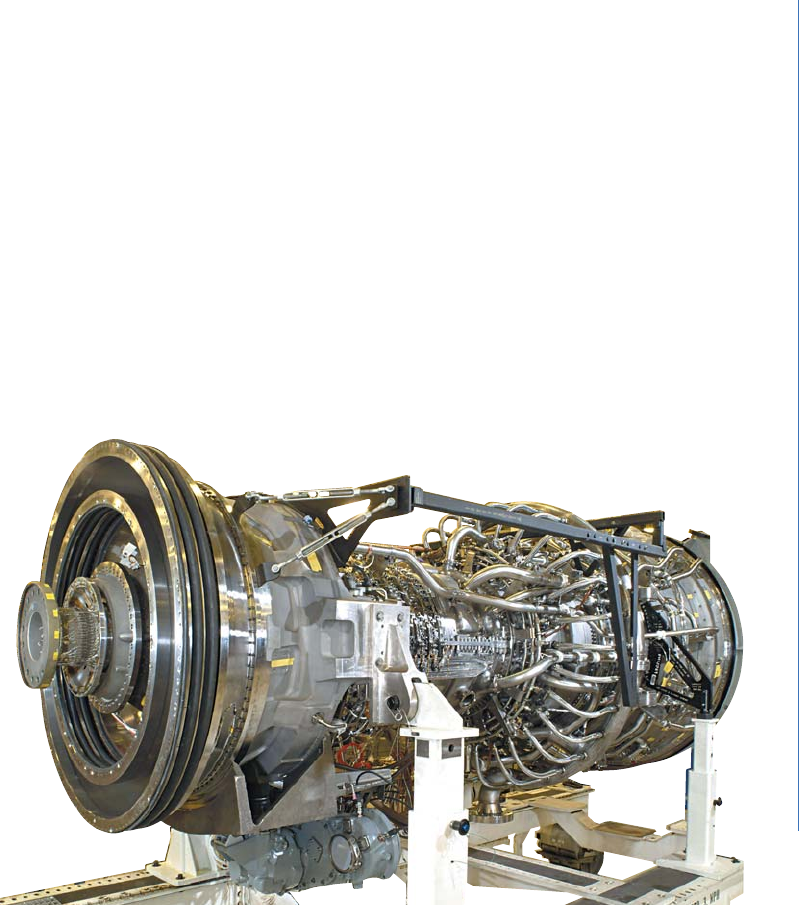

The LMS100‚ is a simple-cycle, three-shaft gas turbine that uses intercooling technology to increase

power and efficiency. At more than 100MW, or 134,000 shaft horsepower and 46% efficiency, the

LMS100 provides the highest level of performance of any aeroderivative gas turbine today.

Combining GE Aviation’s highly successful CF6-80C2/80E high bypass turbofan engine and

GE Energy’s Frame 6FA+e gas turbine, this powerful machine represents the most extensive

collaboration of design and manufacturing expertise in the history of GE.

The LMS100’s aeroderivative core and free power turbine allows operating flexibility not seen in any

other gas turbine of its size. The free power turbine is ideal for mechanical drive applications due to

the simple change-out of the first stage Power Turbine nozzle to optimize performance for 3,000 or

3,600 rpm drive shaft speeds. The part power efficiency of the LMS100 is greater than other gas

turbines at maximum power. The modular design and ability to change-out the supercore (core +

intermediate pressure turbine assembly) engine in 24 hours, provides increased availability. The

LMS100 utilizes a single design for 50Hz, 60Hz and mechanical drive with one common gas turbine,

improving fleet reliability.

17 GE

Gas Turbines

LMS100 Aeroderivative Gas Turbines

LMS100 Gas Turbine

GENERAL SPECIFICATIONS

Compressors

- Two axial compressors (LPC, HPC)

- LPC first 6 stages from GE MS60001FA+e

- HPC 14 stage from CF6-80C2/LM6000

- Pressure ratio 42:1

Combustion and Emissions Control

- Annular combustion chamber (30 fuel nozzles)

- Dry Low Emissions (DLE) available 2009

(15 premixers)

- Water or steam injection for NOx abatement

- DLE available in 2009

Turbines

- Three turbine sections (HPT, IPT, PT)

- HPT 2 stage air-cooled

- IPT 2 stage

- PT 5 stage (variable speed)

Package

- Gas turbine driver package with enclosure

- Auxiliary skid mounted in front of the

package for short easy connections

- Package factory wired to I/O packs in

terminal box for increased reliability – Fiber

optic cable to control system

Emissions Control

- Water or steam injection for NOx abatement

- DLE available in 2009

- Gas Turbines 1

- Contents 2

- GE10 Gas Turbines 4

- GE10-1 Gas Turbines 5

- GE10-2 Gas Turbines 6

- MS5001 Gas Turbines 8

- MS5002C-D Gas Turbines 9

- MS5002E Gas Turbines 10

- MS6001B/MS7001EA/MS9001E 11

- PGT16 Gas Turbine 12

- GAS GENERATOR 13

- POWER TURBINE 13

- PGT25+ Gas Turbine 14

- PGT25+ G4 Gas Turbine 15

- LM6000 Gas Turbine 16

- LMS100 Gas Turbine 17

- Main Components 18

- Gas Turbine Operability 20

- CPC Logic 21

- Pipeline Transportation 23

- Refinery and Petrochemicals 24

- Test Facilities 25

- Training 27

- Generator Drive 28

- Mechanical Drive 29

- (*) including auxiliary skid 30

- (***) gas turbine package 30

- GE imagination at work 31

Comments to this Manuals